3D Printing

Designcraft uses advanced 3D printing to bring your designs to life quickly and accurately, with production-quality finishes and materials.

We use advanced stereolithography technology and polyjet printing to produce complex geometries with superior resolution, clarity, and finish quality. Our 3D printing technology supports both rigid and flexible materials—ideal for simulating overmolds, gaskets, or functional components in early prototypes, and a single 3D printed master can serve as the foundation for dozens of cast parts in different durometers and finishes.

For added precision, we can CNC machine features that exceed the resolution of 3D printing, and integrate lighting, mechanisms, and functional elements.

Stereolithography (SLA) Capabilities

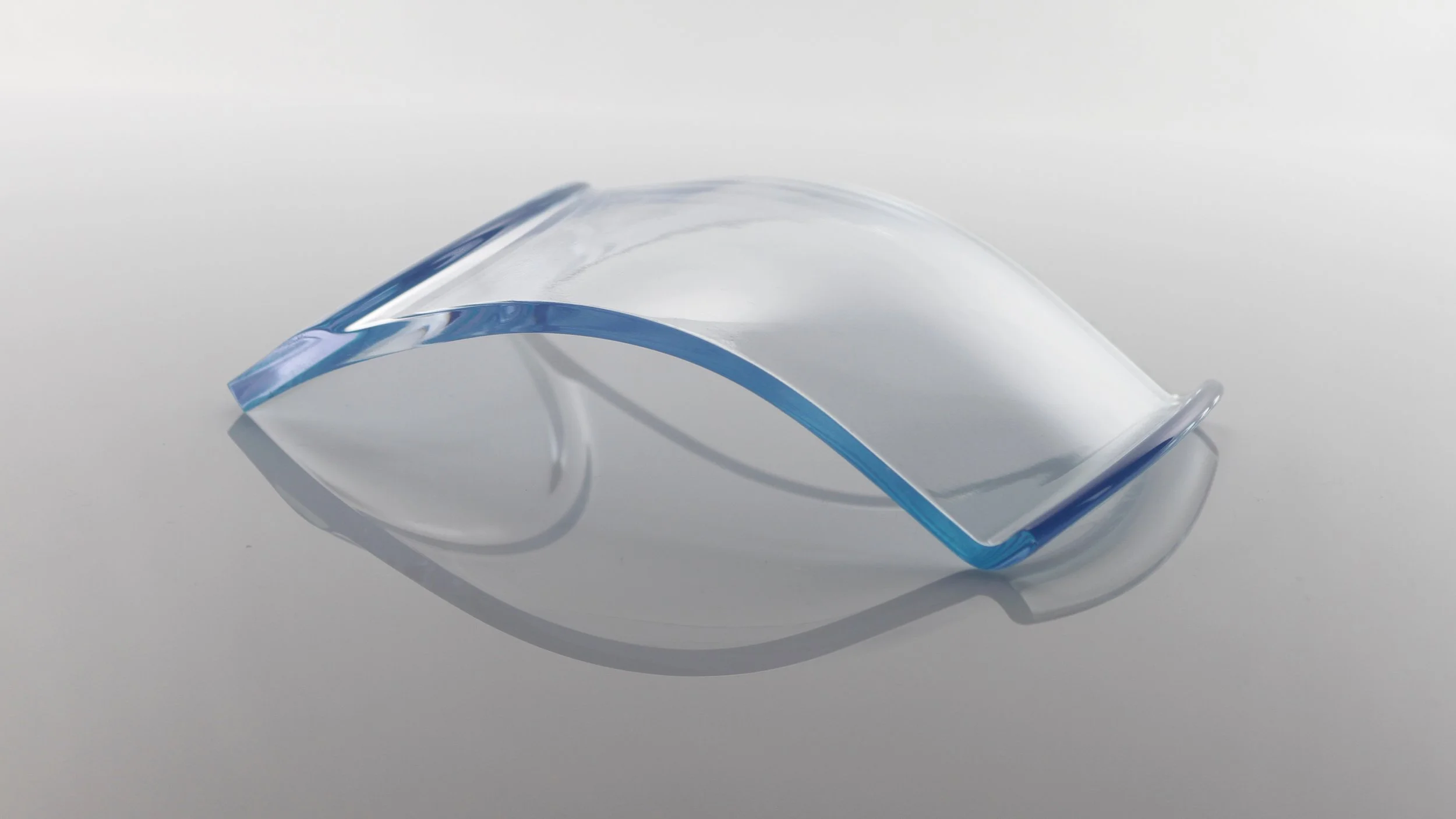

Crystal-Clear Prototypes

Looking for a cost-effective way to produce crystal-clear visual models or engineering prototypes? From bottles and bowls to lenses, optics, and light pipes, our SLA process can mimic transparent parts for a wide range of applications.

Flexible and Functional

Capable of reproducing incredibly complex geometries, SLA can be used for engineering prototypes, concept models, and even masters for silicone tooling. The material resists moisture and humidity, supports brass inserts, and can be cosmetically painted or textured.

Large Scale Savings

Our SLA process offers a generous build volume of 25" x 29" x 21", which allows us to produce larger parts than most other 3D printers. This expanded capacity is efficient and cost-effective for both large components and multi-part runs.

Polyjet Printing Capabilities

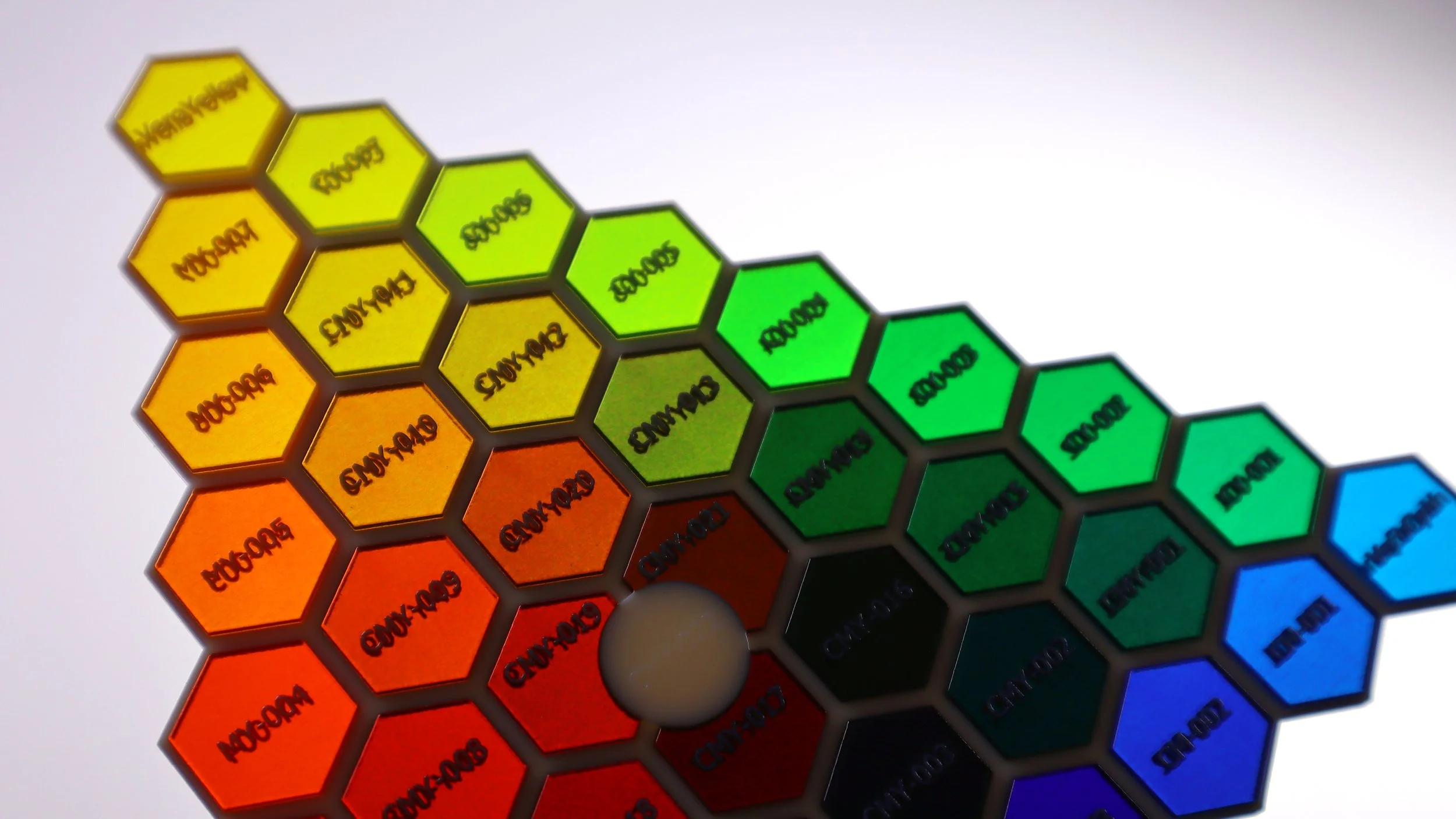

Multi-Material and Multi-Color Printing

PolyJet printing allows us to print parts at .0005” layer thickness, blend rigid and flexible materials, and incorporate an extensive library of Pantone colors—all at the same time. It’s the perfect way to create prototypes with rubber-like grips, rigid housings, and full-color details, simultaneously.

High Resolution Graphics and Textures

Beyond dimensional accuracy, PolyJet printing can reproduce fine surface detail through advanced 3D texture mapping. Features such as wood grain, surface dimples, embossed logos, and other tactile details can be accurately simulated without post-processing. The result is a prototype that both looks and feels like the real thing.

Rapid Iteration with Realism

Whether you need a single multicolor showpiece or multiple prototypes that perform, PolyJet printing delivers unmatched realism—quickly and cost-effectively communicating fit, form, and function.